In this tip of the month (TOTM) we will present the results of several case studies showing the effect of gas molecular weight on the performance and efficiencies of centrifugal compressors. We have considered several “what if” scenarios such as variation of compressor speed as a function of molecular weight, while maintaining the same suction and discharge pressures and mass flow rate. Variation of polytropic head and efficiencies as a function of gas molecular weight for a given compression ratio, and compressor speed has also been studied. In addition, the impact of thermodynamic properties package has been studied.

Compressors can be generally classified in two categories:

- Positive displacement; this type of compressor includes reciprocating, rotary screw, sliding vane, liquid ring and rotary lobe. The compression principle is volumetric displacement – reducing the gas volume increases pressure.

- Kinetic or Dynamic: this type of compressor includes centrifugal and axial compressors. The compression principle is acceleration and deceleration of the gas – kinetic energy is converted to pressure rise.

Reciprocating and centrifugal compressors are the most popular compressors used in E & P applications. Rotary screw compressors are gaining in popularity in low to moderate pressure gas boosting service, refrigeration systems and fuel gas compression for gas turbines. Further detail may be found in reference [1].

From a calculation viewpoint alone, the power calculation is particularly sensitive to the specification of flow rate, inlet temperature and pressure, and outlet pressure. Gas composition is important but a small error here is less important providing it does not involve the erroneous exclusion of corrosive components. A compressor is going to operate under varying values of the variables affecting its performance. Thus the most difficult part of a compressor calculation is specification of a reasonable range for each variable and not the calculation itself. Maddox and Lilly [2] emphasize that using a single value for each variable is not the correct way to evaluate a compression system.

Normally, the thermodynamic calculations are performed for an ideal (reversible process). The results of a reversible process are then adapted to the real world through the use of an efficiency. In the compression process there are three ideal processes that can be visualized: 1) an isothermal process, 2) an isentropic process and 3) a polytropic process. Any one of these processes can be suitably used as a basis for evaluating compression power requirement by either hand or computer calculation. The isothermal process, however, is seldom used as a basis because the normal industrial compression process is not even approximately carried out at constant temperature.

Due to practical limitation the compression ratio per stage is often in the range between 2 and 6. For large overall compression ratio applications multistage compressors are used. The choice of the interstage pressure is an economic decision and can be estimated by equal compression ratios for each section but may be adjusted to minimize total power requirement.

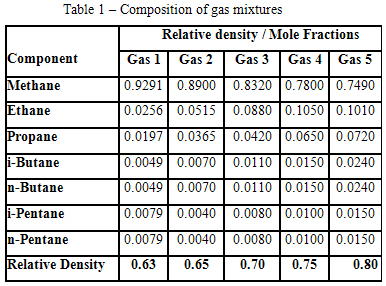

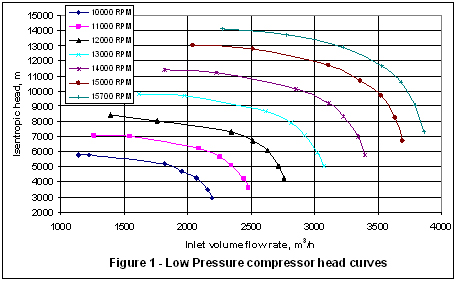

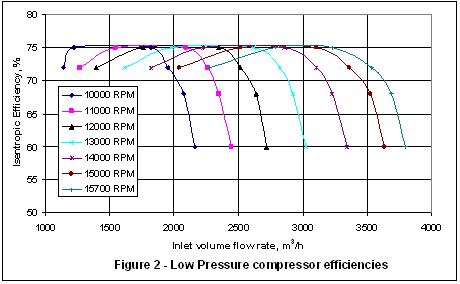

In order to study the effect of feed gas molecular weight on the performance of centrifugal compressors, several computer simulations using HYSYS [3] were performed. The gas mixtures with the composition shown in Table 1 with molecular weights ranging from 18.2 to 23.17, corresponding to relative density of 0.63 to 0.80, respectively, were used in this study. The characteristics curves for the centrifugal compressors used in this study are shown in Figures 1 and 2. These performance curves were supplied to the simulation software and used in the course of simulations.

Case 1: Effect of Molecular Weight on Flow Rate for Fixed ?P (Constant Speed)

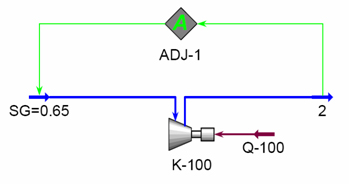

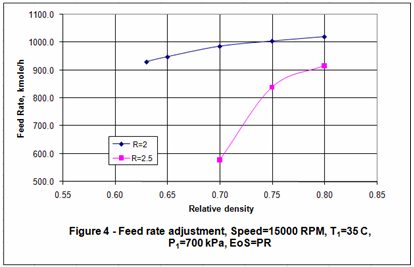

For a fixed inlet pressure of 700 kPa, 35 °C, and 15000 RPM, the feed gas relative density was varied from 0.63 to 0.80 with an increment of 0.05. In order to maintain the outlet pressure, the feed flow rate has to vary. We are essentially fixing P1 and P2 and wanting to see the effect on the compressor of varying molecular weight feed. The set up shown in Figure 3 was used to generate the simulation results. The simulation results for compression ratios of 2.0 and 2.5 are shown in Figure 4. The PR EOS [4] is used for thermodynamic properties calculations.

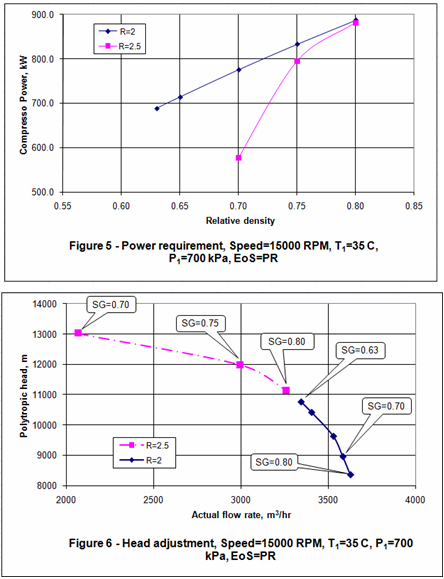

Figure 4 indicates that as the relative density decreased, the flow rate must decrease. Note, for the case of compression ratio of 2.5, no convergence could be achieved for relative density of 0.63 and 0.65 due to the fact the surge limit had been reached. For the same case, the required power as a function of relative density is shown in Figure 5. Since, the flow rate decreased with decreasing relative density, the required power decreased.

Finally, the variation of polytropic head as a function of inlet actual volumetric flow rate is shown in Figure 6. Note that the relative densities are identified on this diagram to show their influence on the performance of the compressor.

Case 2: Variable Speed

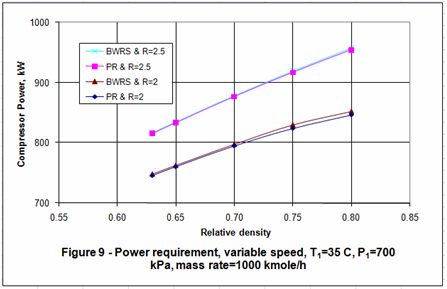

As in the case 1, for a fixed inlet pressure of 700 kPa, 35 °C, and mass flow rate of 1000 kmol/hr, the feed gas relative density was varied from 0.63 to 0.80 with an increment of 0.05. In this case, the compressor is varying speed to maintain flow rate at the ![]() P speed imposed on it. The schematic setup to generate simulation results is shown in Figure 7. The simulation results for compression ratios of 2.0 and 2.5 are shown in Figures 8 and 9. In addition to the results by the PR EOS, the results obtained by BWRS are shown on these diagrams. The difference between the results of these two EOS for these cases is negligible.

P speed imposed on it. The schematic setup to generate simulation results is shown in Figure 7. The simulation results for compression ratios of 2.0 and 2.5 are shown in Figures 8 and 9. In addition to the results by the PR EOS, the results obtained by BWRS are shown on these diagrams. The difference between the results of these two EOS for these cases is negligible.

As shown in Figure 8, as the relative density increases, the compressor speed dropped. However, as relative density or molecular weight increased, the required power increased, see Figure 9.

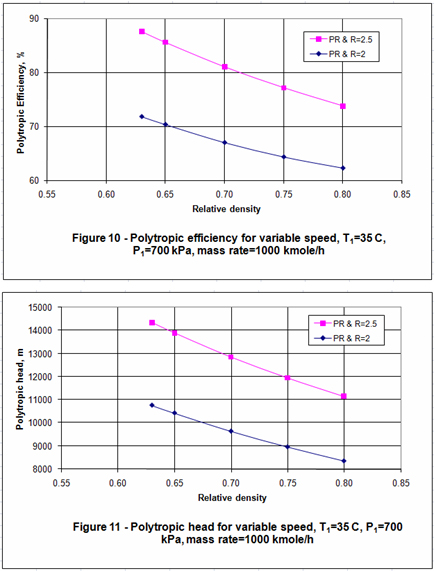

As shown in Figures 10 and 11, the polytropic efficiency and head decrease with relative density. More detail of simulation results can be found in Reference [5].

Conclusions

The impact of relative density (molecular weight) on the performance of a centrifugal compressor was studied by performing a series of computer simulations. Based on the simulation results, it is found that:

- For the same feed condition, compression ratio, compressor speed, the flow rates must decrease as the relative density decreases, and will eventually approach a surge condition.

- For the same feed condition, compression ratio, compressor speed, as the relative density increases, the flow rate increases which results in more power consumption.

- For the same feed condition and rate, and compression ratio, the compressor speed decreases with molecular weight but as expected, the power requirement increases.

- The PR EOS and BWRS EOS produced the same simulation results

To learn more about similar cases and how to minimize operational problems, we suggest attending our ME44 (Overview of Pumps and Compressors in Oil and Gas Facilities), ME46 (Compressor Systems – Mechanical Design and Specification), G4 (Gas Conditioning and Processing) and G5 (Gas Conditioning and Processing – Special) courses.

By: Dr. Mahmood Moshfeghian

Reference:

- Campbell, J. M., “Gas Conditioning and Processing, Vol. 2, the Equipment Modules, 8th Ed., Campbell Petroleum Series, Norman, Oklahoma, 2001

- Maddox, R. N. and L. L. Lilly, “Gas conditioning and processing, Volume 3: Advanced Techniques and Applications,” John M. Campbell and Company, 2nd Ed., Norman, Oklahoma, USA, 1990.

- ASPENone, Engineering Suite, HYSYS Version 2006, Aspen Technology, Inc., Cambridge, Massachusetts U.S.A., 2006.

- Peng, Y. D., Robinson, D. B., “A New Two-Constant Equation of State,” Ind. Eng. Chem. Fund., 15, 59, 1976

- Moshfeghian, M., Bothamley, M., and Lilly, L.L., “Feed gas molecular weight affects performance of centrifugal efficiency,” Oil and Gas J., May 10, 2008

Dear Sir,

Thank you very much for this article.

We have high stage sour gas injection compressors (Reciprocating Type)( 4stages ) . Could you please advise what will happen if the molecular weight change on reciprocating type compressors? Because the compressor is designed for 20.62 MMSCFD with a design MW of 29 and design suction pressure of 355 psig. But now we are operating at a suction pressure of 310 psig and molecular weight of 24 and the capacity is only 16 MMSCFD.

We don’t know whether the reciprocating compressor capacity is decreased by decrease in gas MW or decrease in suction pressure?

Please advise your comments.

Thanks and regards

R. DEEPAK

Process Engineer

PM Department

Abu Dhabi Oil Co. Ltd., ( Japan )

Abu Dhabi

TEL: +9712-6087461

Mobile:+971508189769

Dear Deepak,

a positive displacement compressor is insensitive to gas composition changes and system resistance. therefore there should not be any decrease in throughput of the compressor.

So the decrease in throughput may be due to some internal mechanical problem like:-

1. Valve losses

2.Piston ring leakages

3.Packing leakage.

4.’Dead Volume”.

5. Less RPM of compressor.

Regards

Abhimanyu Dagla

Production Engineer

ONGC India

In addition, the suction pressure is also less, which will result in high compression ratio, and lower volumetric efficiency, and thus lower throughput.

You can contact me with the complete details of your recip compressor.

it includes

1. design conditions- pressures/temperatures, efficiency, compression exponent/flow rate/ BHP

2. operating conditions- pressures/temperatures, efficiency/compression exponent/flow rate/BHP.

Abhimanyu Dagla

Production Engineer

Oil and Natural Gas Corporation Limited, India.

And, lastly, you can consider changing orifice plate because the molecular weight has been changed. Less the Molecular weight, less will be the pressure drop across orifice, and vice versa.

regards

Abhimanyu Dagla

Production Engineer

Oil and Natural Gas Corporation Limited, India.

Dear Abhimanyu,

On a scale of 0-10…with 10 being most valuable, please confirm the value of providing real time density information to improve the performance efficiency of axial and centrifugal compressors in Hydrocarbon Gas service. Also, the concept of providing real time heating value information for turbines in service, where the heating value of the fuel varies.

If there is promise here, I am interested in pursuing the evaluation and measurement of this concept. The technology would be non-intrusive. I am an independant consultant who works with the Oil & Gas industry.

Please respond and thanks for your expertise.

Jon Cloy

Houston, TX

Item 4/ of the conclusion:

How is it possible to assume a constant feed condition (composition?) and an increase in molecular weight?

Please don’t consider my previous comment (please delete it).

Another point is that, depending on the suction pressure control scheme, the number of mole can actually decrease as the molecular weight (relative density) increases.

This is explained in “A Working Guide to Process Equipment” by Norman Lieberman.

dearsir

what is effect of high molucalar weight of gas on compresser power consuption and it can be controlled

Probably, a higher MW will be assosiated with a higher head generation and higher power consuption?

“3 -For the same feed condition and rate, and compression ratio, the compressor speed decreases with molecular weight but as expected, the power requirement increases.”

Vendor compressor curves show that for same actual flow and same head, the required speed is reduced as the moleculare weight increases. For lower molecular weight, the required speed is increased. For both cases, the power requirement remains almost not changed.

“3 -For the same feed condition and rate, and compression ratio, the compressor speed decreases with molecular weight but as expected, the power requirement increases.”

The above statement is inline with updated vendor’s curves.

Thanks for the informative TOM.

Dear Sir,

Thanks for the informative literature.

I would like to have more specific data on how the surge limit / capacity is affected by the change in molecular weight. We have a compressor application under commissioning where the mol weight will be 21 at start of plant and gradually over a period of one week, the mol weight will reduce to the specified value of 17. The permanent operation of compressor will be with mol weight as 17.

In such case, I am interested in knowing how the surge line should be drawn during site test – whether based on 21 or on 17. Which will be safer? What would be the method for commissioning such a service?

Request you to review and advise with your comment.

thanks and regards,

Suhas Lonakadi

kind regards,

When choosing a mechanic, ask if they’ve worked on your model of car before. If the mechanic says they have, then they are likely aware of just what repairs need to performed in order to have your car operating well again.

As I read article above, question is if a centrifugal compr is designed for 17 MW gas of say 60000 lb/hr rate, for a DP of 45 psi, should it be able to process gas of same rate at MW of 30 with same DP? Will efficiency, stagewise compression ratio etc remain same? Tell me what you can. thanks

With fixed inlet condition,suction pressure, temperature and fixed outlet pressure, with only change in molecular weight of feed (feed composition) the change is power is like, if molecular weight is increasing then power requirement will be decreasing.

Is it right, if not than explain, please.

what is the effect of inlet gas density variation on the thrust load of centrifugal compressor

Hello just wanted to give you a quick heads up and let you know a few of the images aren’t loading correctly. I’m not sure why but I think its a linking issue. I’ve tried it in two different internet browsers and both show the same results.

Thanks in favor of sharing such a good opinion, pareagraph is nice, thats why i

have read it entirely

You’ve got a great blog here! would you like to create some invite posts on my blog?

I will like to know how, Using a positive displacement reciprocating compression, how the entire process of its operations can be establish using the appreciation and understanding of thermodynamic

Sir,

I want to calculate the minimum molecular weight at which the compressor can run without surging.

It would be very helpful if you suggest any material where i can find the way to calculate it

Regards

Y Bhargav Ram

Sir,

in the introduction to case 2, you have used the term mass flow as 1000 kmol/h. That should instead be termed as molar flow. This is necessary because though molar flow may remain the same, mass flow through the compressor will vary with molecular weight and using the terms interchangeably will lead to confusion.

It is also for this reason only that the compressor power increases with molecular weight, even after reduction in speed, as the mass flow through the compressor increases.

Everyone loves what you guys are up too. This kind of clever work and exposure! Keep up the superb works guys I’ve incorporated you guys to blogroll.

I have an important question about consumed power in compressor, I read in this article that the mentioned power increases with molecular weight i.e higher molecular weight needs higher power, but when I tried different composition in Hysys, I found that higher molecular weight needs lower power. Of course with the same feed conditions (pressure and temperature) and same molar flow rate.

Are my calculations right or not, and please explain the reason of any result.

I know that mass flow rate will increase with molecular weight, yet I have noticed that the consumed power in compressor depends on volume flow rate not mass flow rate.

If somebody helps me in this issue, I will appreciate it so much.

Best Regards,

I’m curious to find out what blog platform you have been utilizing? I’m experiencing some small security issues with my latest blog and I’d like to find something more safe. Do you have any recommendations?

I was wondering if you ever thought of changing the layout of your blog? Its very well written; I love what youve got to say. But maybe you could a little more in the way of content so people could connect with it better. Youve got an awful lot of text for only having 1 or two images. Maybe you could space it out better?

We have Steam turbine driven CO2 centrifugal compressor 2 casings (LP/HP) with 2 stages in each Casing. Recently abnormal decrease in 3rd stage (HP) discharge temperature observed with increase in pressure. Temp reduced from 180 deg C to 140 deg C and pressure increased to 6 bar g.

Correspondence with OEM indicated that Labyrinth seal between 3rd and 4th stage might have damaged which is causing low temp (40 deg C) 4th stage suction gas to mix with 3rd stage discharge gas. There is a cooler between 3rd stage discharge and 4th stage suction. Also pressure increase is occurring due to mixing of cold gas. We have also noticed low through put from the compressor, means some thing has happened.

I have few queries regarding understanding of this theory and need your expert opinion.

1) Is it possible for 4th stage gas to travel back to 3rd stage through damaged labyrinth, when pressure of 4th stage will be slightly lower due to piping/cooler pressure drop?

2) Even is gas travelling from 4th to 3rd stage suction, it is mixing after the impeller tip. Will discharge pressure of 3rd stage increase when gas is travelling through diaphragm?

3) Is there any other cause of decreasing the 3rd stage discharge temp and increase of pressure?

In past we have faced issues with scaling inside this HP casing between stages, due to process issues.

Need your urgent and kind reply so that proper actions can be taken.

Thanks and Best regards,

Dear Sir,

Thanks for wonderful article.

I have a query regarding our Centrifugal compressor. What will be the effect of specif gravity of gas in flow. For example if I achieved 175000 Nm3 of flow with S.g. of 0.95 what will be the minimum flow with s.g. of 0.54 considering the suction and discharge pressure is same.

Dear Sir,

Thanks for wonderful article.

I have a query regarding our Centrifugal compressor. What will be the effect of specif gravity of gas in flow. For example if I achieved 175000 Nm3 of flow with S.g. of 0.95 what will be the minimum flow with s.g. of 0.54 considering the suction and discharge pressure is same. Would we get more flow with less s.g.??

hi

i’ve got a question, can anybody please answer?

for a given compressor we can use affinity law with current head-flow chart to obtain new chart in different rpm, but my question is this: how would rpm change polytropic efficiency? is there any non-dimensional number like the ones that we use in affinity law? the author of this article draw isentropic efficiency-flow rate for different speeds, but as the chart shows here the peak efficiency is unchanged and here is the most important part. should not the peak efficiency change?

Sir,

My Questions

1. If the centrifugal compressor is measured in Kg/hr instead of mol/hr. On what reason compressor load is increasing, is it because of increase in mass flow/volume flow.

2.Please explain what is “as expected ” implies in the following conclusion

‘For the same feed condition and rate, and compression ratio, the compressor speed decreases with molecular weight but as expected, the power requirement increases.’

Thank You in advance

Sir,

My Questions

1. If the centrifugal compressor is measured in Kg/hr instead of mol/hr. On what reason compressor load is increasing, is it because of increase in mass flow/volume flow.

2.Please explain what is “as expected ” implies in the following conclusion

‘For the same feed condition and rate, and compression ratio, the compressor speed decreases with molecular weight but as expected, the power requirement increases.’

Thank You in advance

Dear sir,

Thank you for your articles.

I am a beginner and I want to know the behavior of temp. and pressure at equal conditions of sour gas (h2s+co2) and sweet gas(methane, ethane etc) when compressing to 4600psi.

what happen if suction temperature increase where all suction pressure ,pressure ratio,feed composition are same?