The process gas pressure has a significant effect on the choice of hydrocarbon dewpoint (HCDP) control process. If the process inlet pressure is less than about 8000 kPa (1160 psia) and the sales gas pressure is 6900 kPa (1000 psia) or higher, the most common process choice is mechanical refrigeration. There are exceptions to this, particularly for very lean gases where a silica gel adsorption system may be a better choice [1].

If the sales gas pressure is low, e.g., gas turbine fuel, 3500-4100 kPa (500-600 psia), an expansion process is often more economic due to the availability of “free” pressure drop [1].

Expansion processes are the preferred alternative when the inlet gas pressure is at least 20-30% greater than the sales gas pressure. This is particularly true at pressure above about 8000 kPa (1160 psia) because mechanical refrigeration systems are generally not effective at high pressure due to the retrograde phase behavior of the gas. If the inlet pressure is provided by the reservoir and no inlet compression is required, the valve expansion process might be more economical when inlet pressure to sales gas pressure ratio exceeds about 1.5 [1].

If the inlet pressure is provided by compression or when the ratio of inlet to sales gas pressure falls to about 1.1 to 1.5 an expander process is often preferred. Table 15.5 of reference [1] provides a comparison between mechanical refrigeration, valve expansions, and expander/compressor processes.

The details of a mechanical refrigeration, silica gel, valve expansion, and expander processes are given in Chapters 6, 15 and 18 of the Gas Conditioning and Processing, Volumes 1 and 2 [1, 2].

Continuing the June 2019 [3] Tip of The Month (TOTM), this tip investigates the impact of process gas pressure on the performance of a mechanical refrigeration plant with mono ethylene glycol (EG or MEG) injection for hydrocarbon dew point (HCDP) control. Specifically, how process gas pressure impacts the gas-gas heat exchanger and chiller duties. The operation of the mechanical refrigeration system will be investigated and reported. In addition, the effect of process gas pressure on the compressor power and cooling duty requirements for gas recycling and pipeline transportation and liquid recovery will be presented.

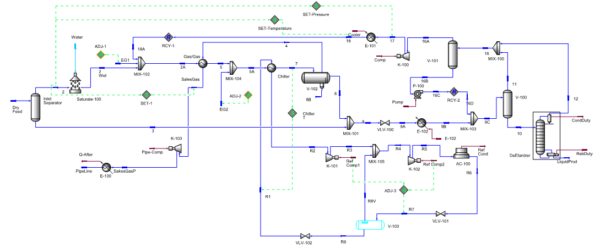

Figure 1 presents the process flow diagrams for a typical HCDP control plant using mechanical refrigeration with MEG injection system. This figure is similar to the June 2019 TOTM [3] which utilizes a flash tank economizer with two stages of compresssion. In this tip, all simulations were performed with UniSim Design R443 software [4] using the Peng-Robinson equation of state.

Figure 1. Process flow diagrams for a HCDP plant using mechanical refrigeration with a flash tank economizer and MEG injection system

Case Study:

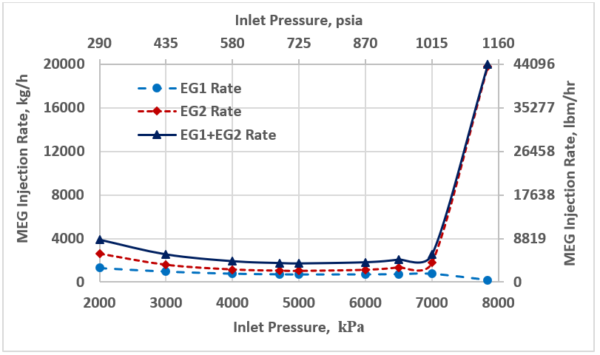

Let’s consider the same case presented in June 2019 TOTM [3] for a rich gas with the compositions and conditions presented in Table 1 [3]. Based on the reported molecular weight and relative density for the C7+ fraction, Table 2 presents the estimated normal boiling point (NBP), critical properties and acentric factor which, are needed by the equation of state. The objective is to meet a hydrocarbon dew point specification at the cricondentherm of -19.5 °C (-3 °F) at about 4708 kPa (682 psia) for the sales gas by removing heat in the “Gas/Gas” heat exchanger (HX) with a hot end temperature approach (TA) of 3°C (5.4°F) and in a propane chiller with TA of 5 °C (9 °F). The heat will be rejected to the environment by a propane condenser AC-100 at 37.8°C (100°F). Pure propane is used as the working fluid in the simulation. The pressure drops in the “Gas/Gas” HX and on the process side of the propane chiller are assumed to be 34.5 kPa (5 psi). The tip will investigate the impact of inlet pressure from 2000 to 7837 kPa (290 – 1136 psia) on the performance of mechanical refrigeration presented in Figure 1.

Table 1. Rich feed gas compositions and conditions

Table 2. Estimated C7+ properties [4]

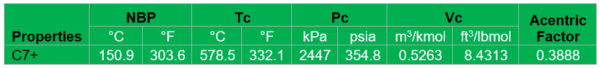

The phase envelope for the feed gas and the desired sales gas specification with a cricondentherm of -19.5 °C (-3 °F) at about 4700 kPa (682 psia) are presented in Figure 2. In addition, Table 3 presents the inlet pressure range, cold separator pressure and the corresponding cold separator temperature to meet the sales gas specifications. The process gas temperatures at the outlet of Gas/Gas HX (Stream 5) are also presented.

Figure 2. Feed gas and sales gas-phase envelopes

Table 3. Inlet pressure, cold separator pressure, the required cold separator temperature and stream 5 temperature to meet sales gas specification

Cricondentherm Pressure and ** Cricondenbar Pressure

The feed gas is flashed in the “Inlet Separator” at 30 °C (86 °F) and the process gas inlet pressure to remove any condensate. The “Inlet Separator” vapor (stream 2) is saturated with water by the “Saturate -100” to form stream “2 Wet” upstream of mixing with MEG hydrate inhibitor, stream “EG1” and the recycle stream “18A” from the deethanizer overhead vapor (located at the right-hand side of Figure 1).

The hydrate formation temperature (HFT) of streams 5 and 7 are estimated. The hydrate inhibitor is injected at the inlet of “Gas/Gas” HX by stream “EG1” and at the inlet of the “Chiller” by stream “EG2”. Streams “5” and “7” cool down below their respective HFTs. The injection rates of streams “EG1” and “EG2” for 80-weight % lean MEG and water solution are estimated manually or by the Adjust tool of UniSim. A design margin of 1 °C (1.8 °F) HFT below the cold temperature for streams “5” and “7” were assumed.

Assuming a TA of 5°C (9°F) and a 6.9 kPa (1 psi) pressure drop in the propane “Chiller” shell side, the pressure of saturated propane vapor leaving the chiller depends on process gas pressure and is in the range of 117 to 200 kPa (17 to 29 psia). Assuming no frictional losses in the suction line to the propane compressor “K-101”, the resulting suction pressure is 117 to 200 kPa (17 to 29 psia).

The condensing propane pressure at the specified condenser temperature of 37.8 °C (100 °F) is 1303 kPa (189 psi). The condenser “AC-100” frictional losses, plus the frictional losses in the piping from the compressor discharge to the condenser were assumed to be 34.5 kPa (5 psi); therefore, the discharge pressure of compressor “K-102” is 1338 kPa (194 psia). The compressors inter stage pressure was determined by equalizing the power for “K-101” and “K-102”. The compressors adiabatic efficiency was assumed to be 75%.

The cold Stream 7 is flashed in the 3-phase separator “V-102” at the separator pressure and corresponding temperature (see Table 3). Assuming this cold separator has no liquid carry over, the vapor stream “4” from this cold separator is used to cool down the incoming warm feed gas in the “Gas/Gas” HX. The heavy liquid stream “8B” (rich MEG solution) from the cold separator is regenerated in the regeneration unit (not shown in Fig. 1) and the lean 80 weight % MEG is recycled and used in streams “EG1” and “EG2”. The cold NGL stream “8” (light liquid phase) from the cold separator, “V-102”, is combined with the plant “Inlet Separator” condensate (stream “3”) in the mixer “Mix-101” to form stream “9”. To prepare the liquid to be fed to the deethanizer, the process specification is to raise the cold temperature of the NGL product stream “9A” to 20 °C (68 °F) and 1500 kPa (217.6 psia) in “E-102” HX, regardless of plant inlet pressure. The process duty and the temperature of the NGL product stream is set by the deethanizer process requirements. The pressure drops in “E-102” HX is 35 kPa (5 psi). Sometimes the heat duty of “E-102” is used as a cooling medium for the deethanizer overhead condenser.

Deethanizer Specifications and Performance:

Like the June 2019 TOTM [3], regardless of inlet pressure, the deethanizer specifications are:

►To recover 90 mole percent of propane of the feed in the bottom product and

►Ethane to propane mole ratio equal to 5 % in the bottom’s product

►Feed pressure 1500 kPa (217.6 psia) and temperature of 20 °C (68 °F)

►Top and bottom pressures are 1450 and 1500 kPa (210.3 and 217.6 psia); respectively

►Number of theoretical stages 12 plus the condenser and reboiler (determined by the material balance and column shortcut calculations)

►Feed tray from top is 4

The deethanizer simulation results for feed gas inlet pressure 4700 kPa (682 psia) are summarized in Table 4.

Table 4. Deethanizer key design parameters for feed gas inlet pressure of 4700 kPa (682 psia)

Impact of Inlet Feed Gas Pressure:

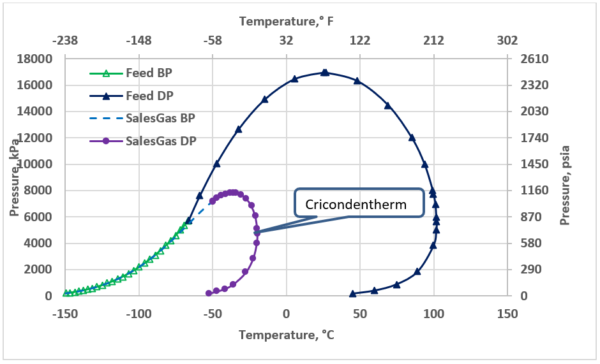

The Gas/Gas HX utilizes the cold temperature of stream 4 to cool down stream 2A and reduce the chiller duty. The specified temperature approach (TA) 3 °C (5.4 °F) sets the sales gas temperature to 30 – 3 = 27 °C (86 – 5.4 = 80.6 °F). Table 3 indicates that increasing the inlet pressure, up to the cricondentherm pressure of about 4708 kPa (682 psia), increases the required cold separator temperature then the cold separator temperature decreases to a minimum at -32.4 °C (-26.3 °F) at sales gas cricondenbar pressure. The “Gas/Gas” HX duty is a function of stream 4 rate and temperature (cold separator temperature). Note that the colder separator temperature results in more liquid drop out and less vapor (stream 4) rate. This may result in lower “Gas/Gas” HX duty and higher stream 5 temperature. The cold separator temperature has a big impact on “Gas/Gas” HX duty and stream 5 temperature. Therefore, streams 5 (Gas/Gas HX outlet) and 7 (Chiller outlet) temperature and their HFT (less the margin) determine the MEG injection rate.

Figure 3 presents the impact of inlet pressure (and the corresponding cold separator temperature) on the MEG injection rate of streams “EG1” and “EG2” upstream of “Gas/Gas” HX and the Chiller, respectively. As the inlet pressure increases, stream 7 temperature initially increases and then decrease. The required MEG injection rate of stream “EG1” remain relatively constant but reduces at the maximum pressure (minimum cold separator temperature) at which stream 5 temperature is 2.7 °C (37 °F). Stream “EG2” rate initially decreases and then increases at higher pressure. The total MEG injection (EG1 + EG2) rate stays the same. The calculated “EG1” and “EG2” were summed up and presented in Figure 3.

Figure 3. Impact of the inlet feed gas pressure on the MEG injection rate upstream of “Gas/Gas” HX (EG1) and Chiller (EG2) (See an alternative figure in the Appendix)

“Gas/Gas” HX cools stream 2A temperature to stream 5 and reduces the required chiller duty. Except for high inlet pressure, typically the “Gas/Gas” HX removes about 70% of the total required cooling duty to meet the specified sales gas dewpoint temperature. Therefore, the chiller duty decreases resulting in lower compressor power, decreased propane refrigerant circulation rate, and reduced propane refrigerant condenser duty requirements.

Both Chiller and “Gas/Gas” HX duties depend on the cold separator temperature. The “Gas/Gas” HX duty also depends on vapor stream 4 rate which decreases with the cold separator temperature. The net effect is an increase in the Chiller and “Gas/Gas” HX duties with the inlet pressure increase. As the chiller duty increases, the compressor power and condenser duty increase, too. Figures 4 A and B illustrate the impact of inlet pressure on the compressor power (K-101 and K-102), “Gas/Gas” HX, Chiller, and condenser (AC-100) duties in SI and FPS system of units, respectively.

Figure 4A. Impact of the inlet feed gas pressure on the Gas/Gas HX, chiller and condenser duty, and compressor power (See an alternative figure in the Appendix)

Figure 4B. Impact of the inlet pressure on the Gas/Gas HX, chiller and condenser duty, and compressor power (See an alternative figure in the Appendix)

To meet pipeline inlet specifications, the sales gas was compressed to 10,000 kPa (1450 psia) in K-103 and cooled to 40 °C (104 °F) in E-100 (located at the lower left corner of Figure 1). Similarly, the deethanizer overhead gas was compressed in K-100 and cooled in E-101 (located at the top of Figure 1) to the stream “2 Wet” pressure and temperature. Figure 5 A (SI) and B (FPS) present the impact of inlet pressure on the required pipeline and recycle compressors powers and the cooler duties for the recycle and pipeline gases.

Figure 5A. Impact of the inlet pressure on the pipeline and recycle gas compressors powers and coolers duties

Figure 5B. Impact of the inlet pressure on the pipeline and recycle gas compressors powers and coolers duties.

Figure 6 presents the impact of inlet pressure on the liquid propane and total liquid rate from deethanizer bottom. Figure 7 presents the impact of inlet pressure on the liquid propane percent recovery (ratio of propane rate in deethanizer bottom to total propane rate in the plant inlet feed gas). It looks like one would want to operate below about 7000 kPa (1015 psia), which is about 10% less than the cricondenbar.

Figure 6. Impact of the inlet pressure on the liquid propane total liquid rate from deethanizer bottom

Figure 7. Impact of the inlet pressure on the liquid propane percent recovery (rate of liquid propane/rate of propane in inlet gas)

Summary:

This tip demonstrated the impact of inlet pressure on the performance of mechanical refrigeration for a HCDP control plant and the following observations were made.

►The cold separator temperature (chilling temperature) is the key design variable and has a significant impact on the performance of mechanical refrigeration.

►The relation between the inlet pressure and the required cold separator temperature to meet the required sales gas specification is nonlinear and complex; therefore, the knowledge of sales gas phase envelope is essential (see Figure 2 and Table 3).

►To minimize the cost, typically the optimum inlet pressure for a mechanical refrigeration process is close to the cricondentherm pressure of sales gas. However, the sales gas pressure and the recycled deethanizer overhead gas compression should be considered.

►The inlet pressure to the HCDP facility cannot exceed the cricondenbar of the sales gas phase envelope.

►Above 7837 kPa [1136 psia] this gas could not be processed in a mechanical refrigeration plant to meet the HCDP specification. This is because at higher pressures you cannot condense enough liquid to meet the specification. One may want to operate below about 7000 kPa (1015 psia), which is about 10% less than the cricondenbar.

To learn more about similar cases and how to minimize operational problems, we suggest attending our G4 (Gas Conditioning and Processing), G5 (Practical Computer Simulation, and Applications in Gas Processing) courses.

By: Mahmood Moshfeghian, Ph.D.

Sign up to receive Tip of the Month email updates!

References

1. Campbell, J.M., “Gas Conditioning and Processing, Volume 2: The Equipment Modules,” 9th Edition, 3rd Printing, Editors Hubbard, R. and Snow–McGregor, K., Campbell Petroleum Series, Norman, Oklahoma, PetroSkills 2018.

2. Campbell, J.M., “Gas Conditioning and Processing, Volume 1: The Fundamentals,” 9th Edition, 3rd Printing, Editors Hubbard, R. and Snow–McGregor, K., Campbell Petroleum

3. Moshfeghian, M.,http://www.jmcampbell.com/tip-of-the-month/2019/06/impact-of-temperature-approach-of-the-heat-exchangers-on-the-capex-and-opex-of-a-mechanical-refrigeration-plant-with-meg-injection/, PetroSkills -John M. Campbell Tip of the Month, April 2019.

4. UniSim Design R443, Build 19153, Honeywell International Inc., 2017.

Appendix

Figure 3. Impact of the inlet feed gas pressure on the MEG injection rate upstream of “Gas/Gas” HX (EG1) and Chiller (EG2)

Figure 4A. Impact of the inlet feed gas pressure on the Gas/Gas HX, chiller and condenser duty, and compressor power

Figure 4B. Impact of the inlet feed gas pressure on the Gas/Gas HX, chiller and condenser duty, and compressor power